Building a Custom Display Kit

With Grandpa’s Cabinets being asked to build more and more display kits for models that are very large, I thought I’d take some time to show just what goes into the building of a Custom Display Kit. The first thing I do is to make a rough drawing of just how the kit...

Two Shelf Custom Custom Display Case

Recently a customer sent along a photo of two items that he wanted displayed in one display case and to just place them next to each other on a single level base just didn’t seem to do them justice. So, after I convinced him to give me artistic freedom I came up...

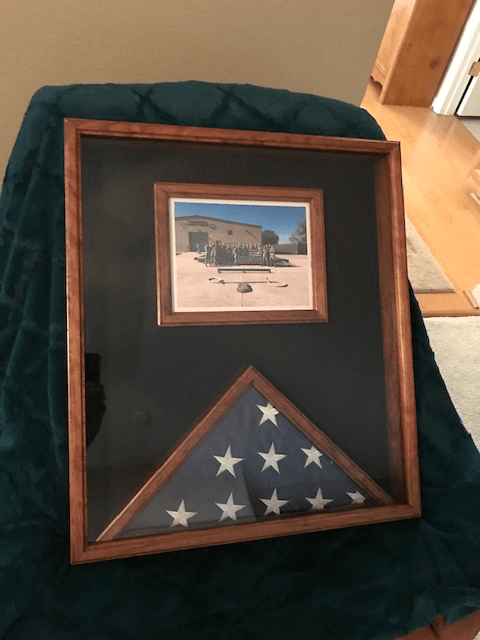

America Flag Display Case

See our American Flag Display Case!

Jim Farrens German Submarine U-552 scale model build

Grandpa’s Cabinets was given the privilege of building a custom display kit to house a spectacular model, hand built by Jim Farrens of the German submarine U-552 from World War II. Jim spent a huge amount of time and money to create a true work of art in his rendition...

New Custom Display Case Base Options

Grandpa’s Cabinets is happy to announce the creation of another option when it comes to your design choices for your next Custom Display Case order – Custom Display Case with an Inset Base